Check valve

Check valves are a key component in the pipeline systems of the petrochemical industry.

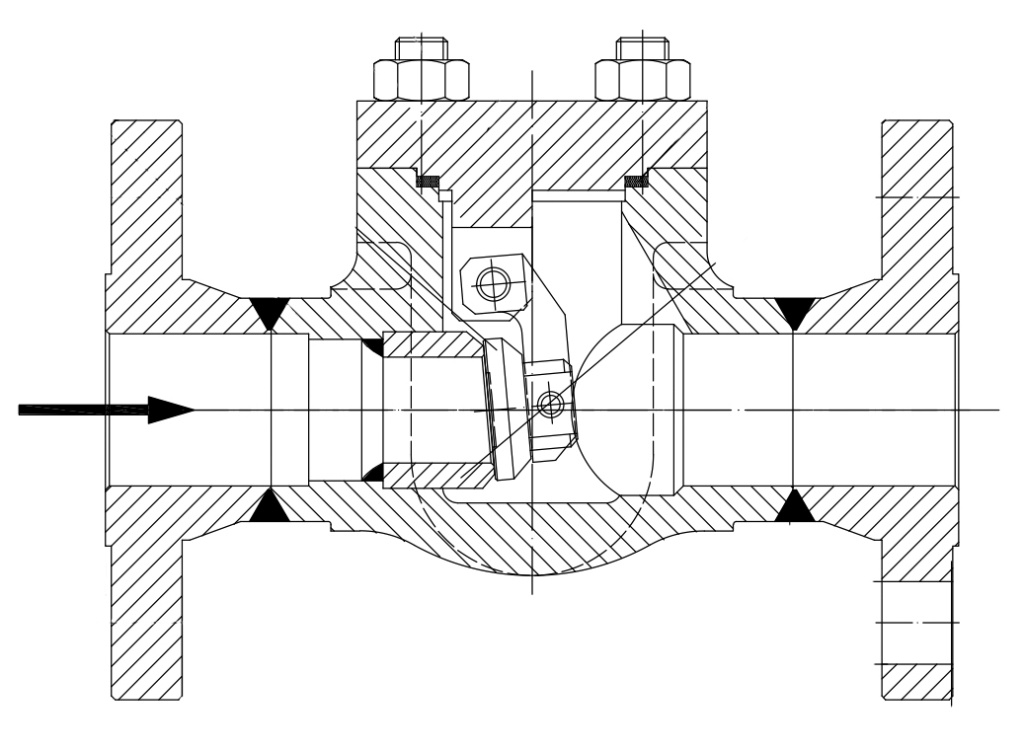

They are designed to prevent backflow of liquid or gas in the pipeline. These valves automatically open when the medium moves in one direction and close when the flow tries to change direction, thereby preventing possible negative consequences of backflow, such as equipment damage or leaks.

Check valves come in 4 types:

• Disc check valve,

• Lift check valve,

• Ball check valve,

• Axial check valve.

Specifications:

Size: Available in various sizes ranging from 1/2 inch to 48 inches or more.

Pressure Class: ASME/API pressure classes include 150Lbs, 300Lbs, 600Lbs and above.

Standard of execution: Meet standards such as ASME B16.34 and API 594.

Body material: Usually made of carbon steel, stainless steel and a variety of alloys selected depending on the operating conditions.

Material of the main internal elements: include stainless steel, alloy steel and special alloys that provide durability and resistance to corrosion.

Type of connection to the pipeline: Flanged, coupling, welded, as well as other types of connections for easy installation.

Control type: Automatic, without the need for external control.

Climate version: suitable for use in a wide range of climatic conditions.

Additional tests: may include cryogenic tests, fire resistance tests, and other specialized tests, depending on the requirements.