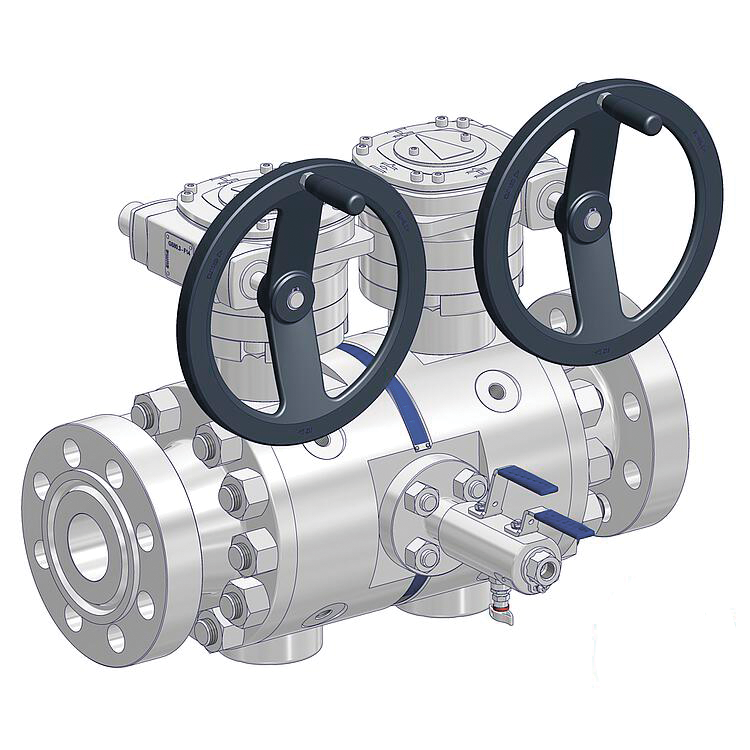

Valves SBB/DBB (Single Block and Bleed/ Double Block and Bleed Ball valve)

SBB (Single Block and Bleed) and DBB (Double Block and Bleed) valves are specialized types of pipe fittings widely used in the petrochemical industry.

SBB valves are designed to simultaneously shut off the flow and relieve pressure in the flanged space.

Whereas DBBs perform double overlap with the possibility of pressure relief between two shut-off elements.

This ensures increased safety and efficiency when working with hazardous liquids and gases.

Specifications:

Size: Usually available in sizes from 1/2’ to 12’.

Pressure Class: ASME/API pressure classes include 150Lbs, 300Lbs, 600Lbs, and even higher for special applications.

Execution Standard: Meet standards such as ASME B16.34 and API 6D.

Body Material: Made from a variety of materials, including carbon steel, stainless steel and special alloys.

Material of the main internal elements: Stainless steel, alloy steel and other alloys selected according to the working conditions.

Pipeline connection type: Flanged, threaded and welded connections for a variety of installation conditions.

Control type: can be equipped with manual control, as well as electric or pneumatic drive.

Climate version: suitable for use in a variety of climatic conditions.

Additional tests: include fire resistance tests, cryogenic tests, and corrosion and high pressure tests.

SBB/DBB valves provide a high level of safety and efficiency in flow management in petrochemical systems, especially in environments where strict safety measures are required.